Services

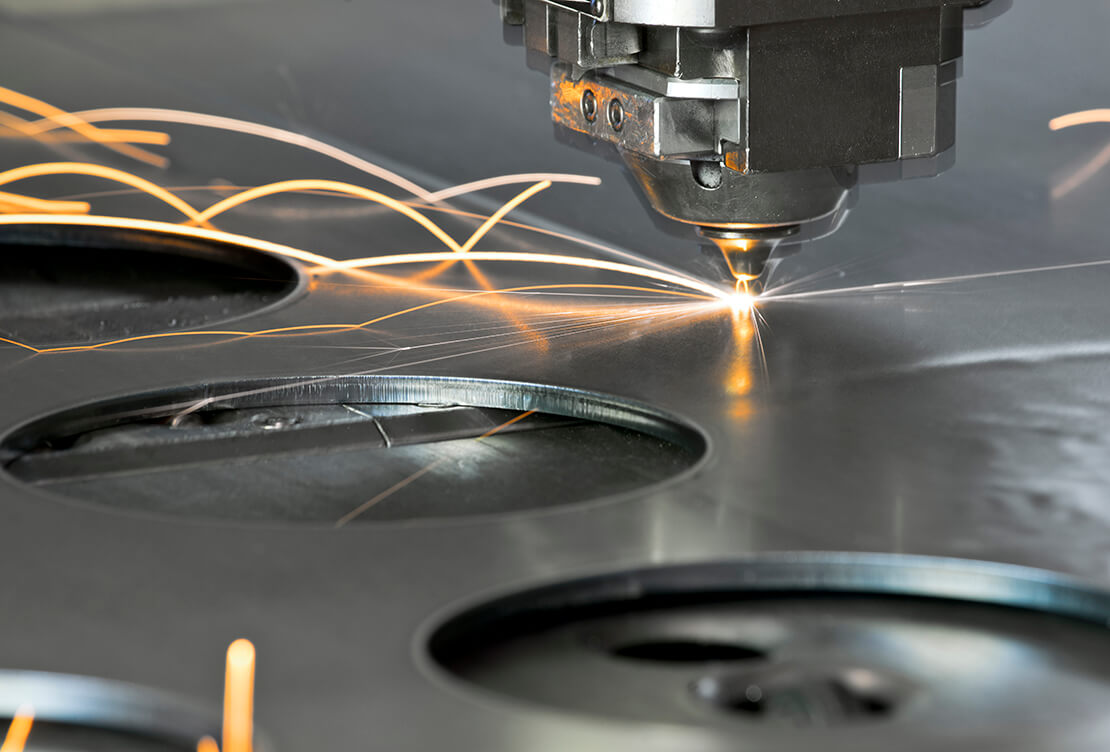

Design and Fabrication

Our design and fabrication capabilities allow us to manufacture and meet tight tolerance requirements and production runs for diverse industry needs. No matter the size of the project, Triten is able to assist and manage the custom fabrication, design and build of projects, from start to finish.

- Custom Tanks

- Custom Stainless-Steel Fabrication

- Pump Base Fabrication

- Boiler Ductwork Fabrication

- Air Supply Systems

- Catwalks

- Ladders

- Stairs and Handrails

- Helipads

- Mezzanines

- Access Platforms

- Custom Harbor Navigation Systems

Maintenance and Repairs

In addition to our preventative maintenance designed to ensure the fewest number of unexpected repairs possible, Triten is prepared to offer emergency maintenance, unexpected maintenance, upgrades, and repairs.

- API 653 Tank Inspections and Repairs

- Automatic and Manual Tank Gauges

- Manway Modifications

- Leak Detection

- Tank Floor Replacements & Repairs

- Tank Level Probes

- Tank Rehabilitation and Modification

- Floating Roof and Roof Seal Installation

- High Level Control Valves

- High and Low Level Alarms

- Fuel Pump and Meter Installation

- Control, Pressure Relieve, and Isolation Valve Installations

- Steel Pipe Installations and Repairs

- Stilling Well Install and Modifications

- Cathodic Protection

- Secondary Containment Repairs

- Petroleum Process Piping

- Pulp and Paper Plant Maintenance

- Marine Dock Repairs

- Steel Equipment Maintenance

Piping and Pipelines

Triten has experienced DOT Certified mobile pipeline welders and fitters currently assisting customers throughout the country. We provide our clients with DOT Certified Hydro Testing Equipment in all areas of pipeline applications.

- Stainless & Carbon Steel Pipe Installations

- Petroleum Process Piping

- High Level Control Valves

- Fuel Pump and Meter Installation

- Install New High Level Control Valves

- Pig Launcher Support

- Bulk Storage and Pipelines

- DOT Level Pipeline Welding

- Cathodic Protection

Shop Facilities

To better suit our clients’ needs, Triten offers on-site or in-house services. For in-house services, Triten has a range of tools at our facilities to properly and efficiently complete the job. We are constantly adding to our selection of tools and services available at our facility, however here are a selection of some of our most frequently requested tools:

- 8 foot & 5/8-inch capacity plate roller

- Do All friction saws

- Welding tools and machinery including acetylene to TIG, and MIG.

- Hydrapower plate shear

- 95-ton Piranja iron worker

- 30-ton overhead crane

- 8-foot plate rolls capability of ¾ inch foot plate

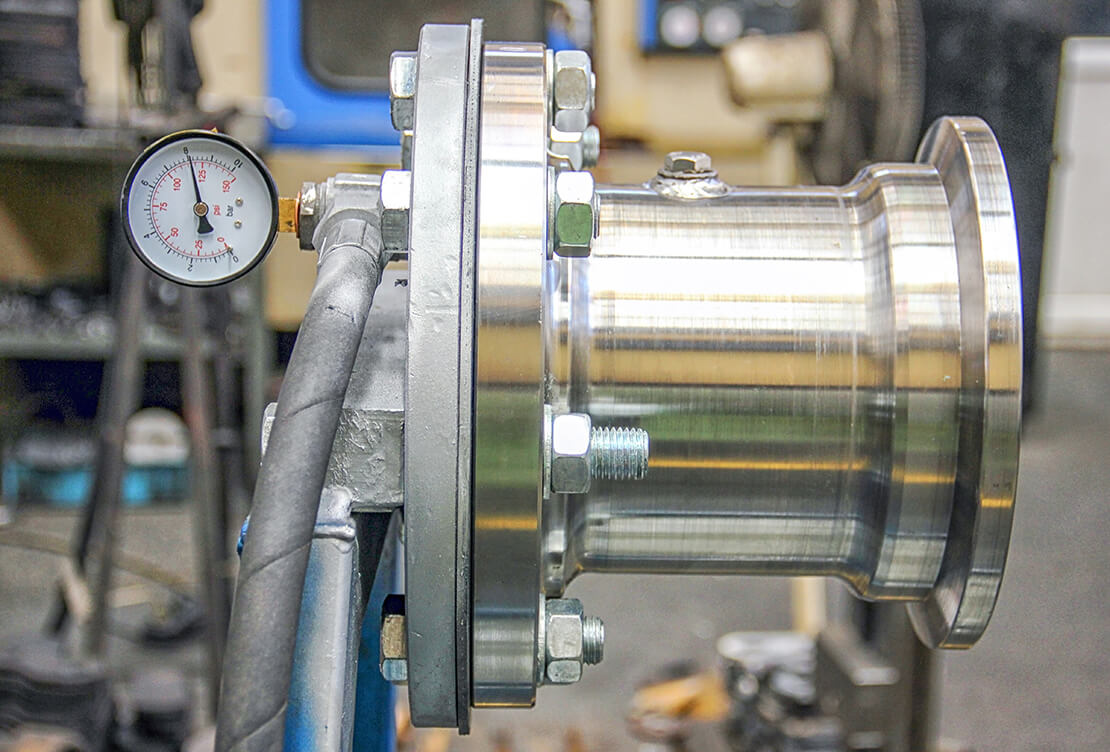

Hydrostatic Testing

Pressure testing is performed to ensure the integrity of a pipeline. The pressure test provides verification that the pipeline is structurally sound by withstanding a required pressure for a specified time period. Pressure testing is normally conducted using water as the test medium (hydrostatic testing).

Conducting a Hydrostatic test

- Identify potential abnormal operating conditions (AOC)

- Utilize the appropriate personal protective equipment

- Pipeline isolation for testing

- Calibration of the testing equipment

- Installation of temperature probs and pressure recording instruments.

- Filling and venting of isolated pipeline segments

- Pipeline pressurization according to specified procedures.

- Data recording of pressures and temperatures

- Documentation and Reporting

Civil and Sitework

Triten is experienced in all types of civil and sitework. When needed, Triten is supported by its affiliate IngenAE, LLC who has a staff of Licensed Professional Civil Engineers and Geologists. Triten carries DOT and ISNET Certifications and has decades of experience of working on and around unmarked utilities and live process piping. Triten routinely performs pre-job safety analysis (JSA), fire watch and can provide a certified person in charge (PIC), certified operator qualifications (OQ) and DOT Qualifications.

- Sitework and Grading

- Underground Piping

- Hydrovac and Dryvac Excavating

- Marine Pile Driving

- Concrete Foundations and Slabs

- Removal of Asphalt and Concrete

- Sludge and Ash Removal and Disposal

- Demolition Services

Specialty Coatings

Triten provides high-quality maintenance and coating application knowledge for both large and small projects.

- Ultra-High Pressure Cleaning

- Tank Linings

- Secondary Containment Coatings

- Cementitious Coatings

- Asset Management Surveys

- Geo-Textile Linings

- High-Temp & Insulative Coatings

- Plural Component Spray Applications

- MIL-Spec Coatings

- Floor Coatings

- Concrete Sealing

- General Painting

Sandblasting

Sandblasting is one of the oldest and most widely used methods for heavy-duty cleaning. Proper preparation before painting or coating is essential to a lasting protective finish. In some cases, removal of an old finish is required. Sandblasting is used for all kinds of applications, most commonly for removing paint and heavy contaminants from metal and concrete surfaces. Triten carefully evaluates each project when our industrial sandblasting services are contracted. Our skilled technicians safely remove old paint, chemicals, rust and dirt while preserving the integrity of the underlying metal. Triten has experienced staff and required tools for all of your industrial sandblasting needs.

- Power Washing

- Pressure Cleaning

- Paint Removal

- Water Blasting

- Water Sealing

- Soda Blasting

- Media Blasting

- Abrasive Blasting

- Sandblasting

- Steam Cleaning